pearling:the machine

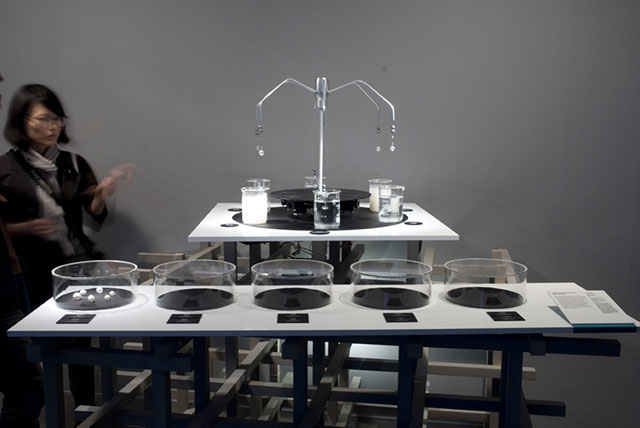

The Pearling machine is based on a dip-coating process. Each pearl is dipped into several baths allowing to build microscopic layers of composite material. After each round, the pearl dries and start the same cycle again.

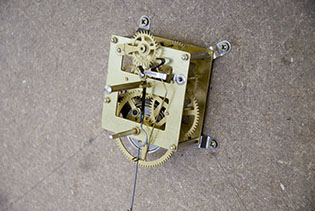

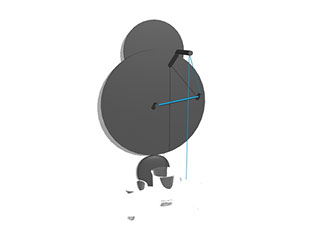

The Pearling machine, was initially build on a clockwork system, as it makes explicit reference to time. The second iteration, developed for the Espace EDF 4 months exhibition in Paris, works on electrical motors and allows to build up 6 pearls at the same time.

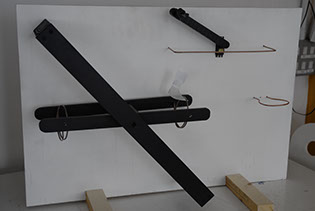

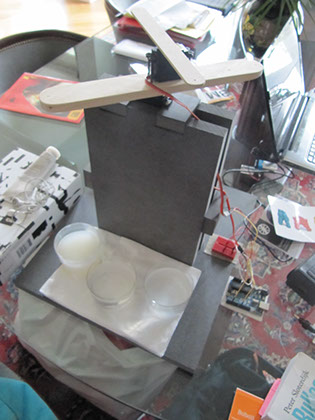

The Pearling machine is still being developed and the process itself is still being optimized in my lab. A prototyping machine, using Arduino and servomotors, allows to have a greater flexibility.

Principle

Design

Availability

VERSION 2.0

Pearling machine 2.0

capacity of 6 pearl

6 servo motors

1 stepper motor

aluminium

PMMA

glass

VERSION 1.0

Pearling from Emile De Visscher on Vimeo.

Pearling machine 1.0

capacity of 1 pearl

1 servo motor

1 pendulum clockwork

PMMA

aluminium

glass

development