petrification:the machine

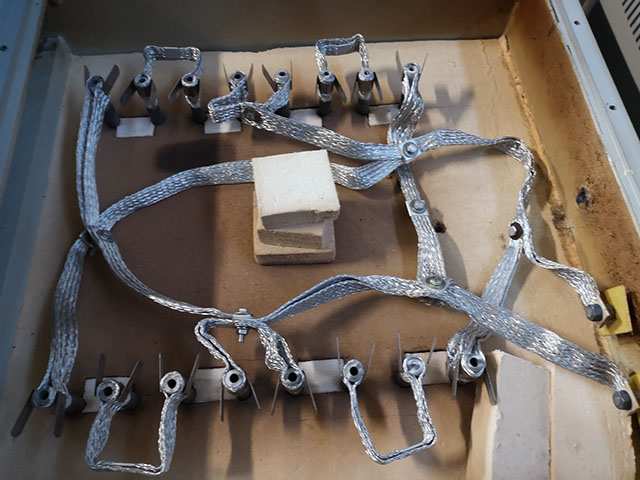

The Petrification process consists of firing the cellulosic pieces at 1400°C, like other ceramics. The main difference resides in the fact that no oxygen can enter the chamber, which can be obtained in two ways : sucking the air with a vacuum pump, or injecting a neutral gaz like Argon.

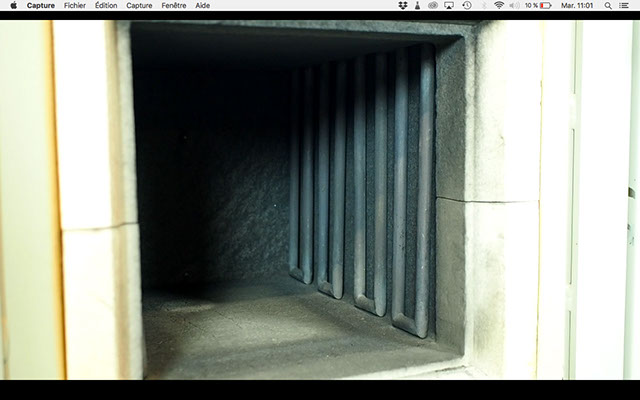

Two versions of the Petrification furnace have been developed. The first one is based on an exhisting ceramic oven, which has then been sealed and added with tubes and valves. The second is based on a chinese atmospheric furnace, optimized for the process.

The Petrification furnaces are quite difficult to transport to different locations. In order to collaborate and experiment, the best way is to come to my workshop in La Courneuve and use them on site.

Principle

Design

Availability

VERSION 2.0 - atmophere

Petrification furnace 2.0

Electrical heating monophase

Control Pannel

PID Controller

vacum pump

Gaz inlet

VERSION 1.0 - hacked ceramic oven

Petrification Furnace 1.0

Hacked cermic oven

Electrical heating

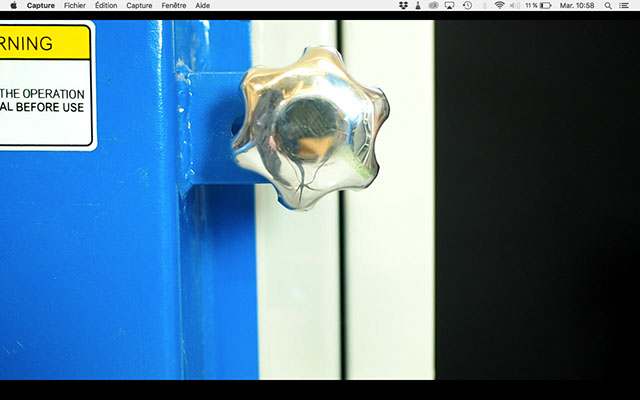

Self-made water valve

Argon gaz atmosphere