polyfloss:the machine

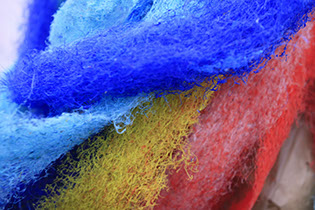

The Polyfloss process is composed of a hot centrifugal extrusion machine. Inspired by candy-floss machines, it has a rotating head, heated, and containing holes on the sides. This allow the shredded waste plastic to be fiberised.

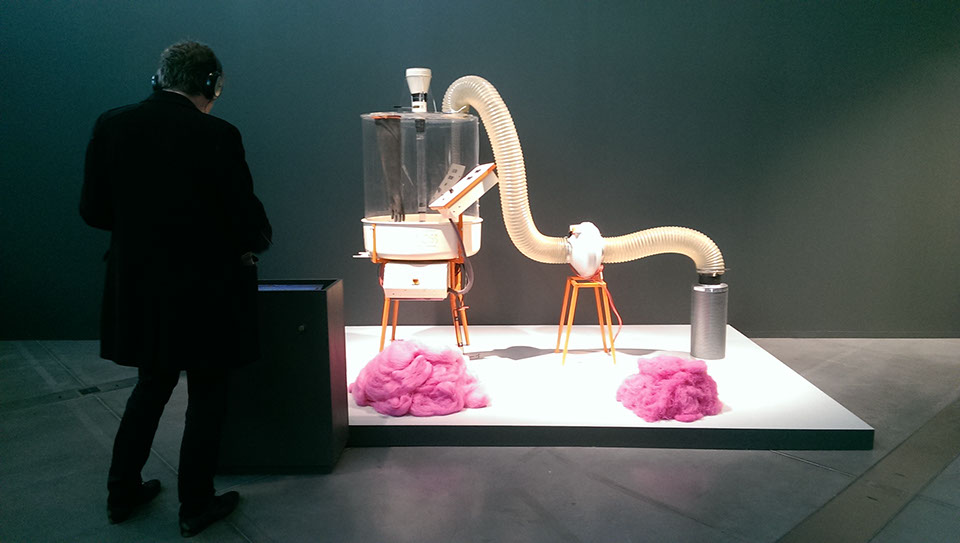

The Polyfloss machines has been developed in several combinaisons, from electrical heating, to gaz and hot air heating. It has a closed acrylic carter and filter to prevent from inhaling fumes or touch molten plastic during use.

The Polyfloss machine can be build on demand, and be adapted to the context's specifications and restrictions. From small scale transportable machines to bigger installations, the Polyfloss team has already worked on several machine types.

Principle

Design

Availability

VERSION 4.0

The Polyfloss Machine 4.0

Electrical heating

Control Pannel

AC Motor and controlers

Extraction

Automatic feeding system and extruder pre-heating technology

VERSION 3.0 - tornado

The Polyfloss Machine 3.0

Electrical heating

Control Pannel

AC Motor

Extraction

Automatic feeding system

VERSION 2.0 - rafale

The Polyfloss Machine 2.0

Gaz heating

DC Motor

Air blowed fiber thining system

Collecting system

VERSION 1.0

The Polyfloss Machine 1.0

Hot Air Heating

AC Motor

Control Buttons

sealable lid

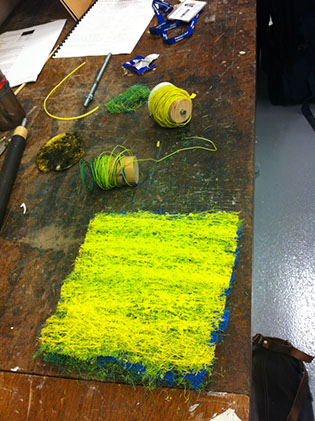

research

.jpg?crc=4168006323)